Bluewater Bio are a global specialist in technologies for cost-effective water & wastewater treatment. Headquartered in London, Bluewater Bio’s range of best in class technologies have been deployed at over 100 sites globally. The Bluewater Bio product, FilterClear, is a high-rate multimedia filtration system which removes suspended solids from a wide range of waters at high filtration rates of 25 m/h and above.

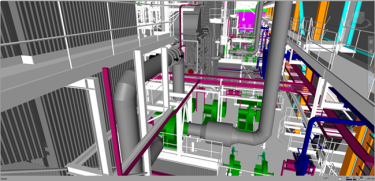

Enisca were engaged by BlueWater bio for the design, provision, installation, testing and commissioning of all mechanical, electrical, control and automation equipment for this offsite build project including:

- Procurement and interior fit out of 20ft high roof shipping container.

- Design and supply Motrol control panel and automation system to control the filter operation including backwash sequence to the agreed control philosophy

- Remotely dial in functionality to enable adjustment to the system operating parameters c/w cloud-based logging of the site data.

- Design and supply of 3400 litre backwash tank

- Installation of pipework, valves and instrumentation

- Insulation, ventilation and air conditioning to maintain the plant room at 25⁰C suitable for ambient air temperatures of 42⁰C

- Provide sufficient ventilation for 2 persons working in the container.

- Process cabling all motors, valves and instrumentation and domestic electrical installation

- Offsite factory acceptance commissioning and testing

Project Details

- Client:Filter Clear

- Scope:Design & Construct DfMA Solution

- Start Date:2019

- Completion Date:2020